- Technology and Innovation

Why Are Shipowners Still Using Outdated Paint When This Japanese Tech Exists?

A Legacy That’s Been Hiding in Plain Sight

For over a century, Chugoku Marine Paints (CMP) has quietly led one of the most crucial sectors in the maritime world—coatings. Not the glamorous kind. The kind that keeps billion-dollar vessels from corroding, slows biofouling, and saves shipowners millions in fuel. While the rest of the industry pours money into new builds and hybrid engines, CMP has been refining the one layer that touches the ocean every single mile of every journey.

More Than Paint: Performance at the Molecular Level

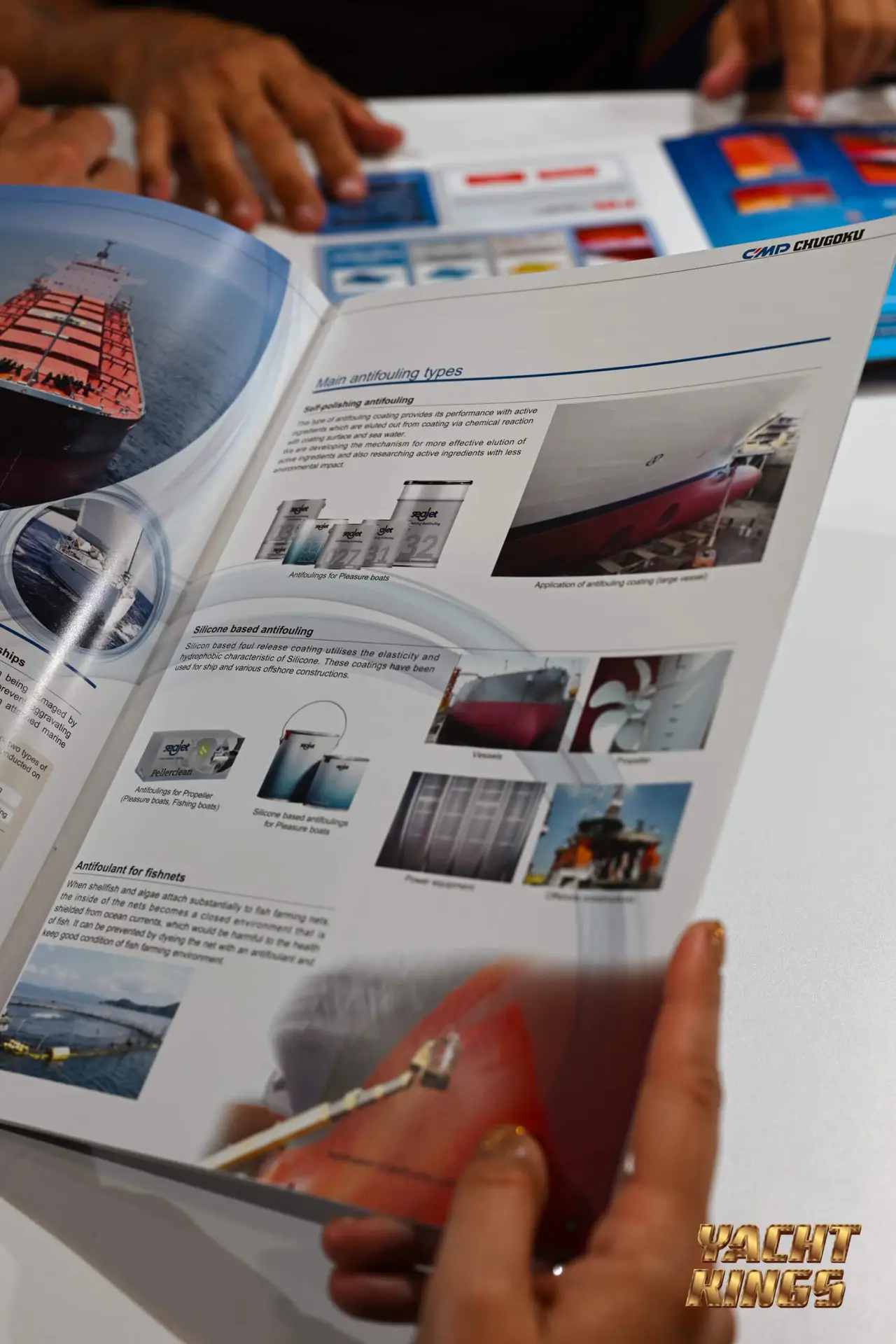

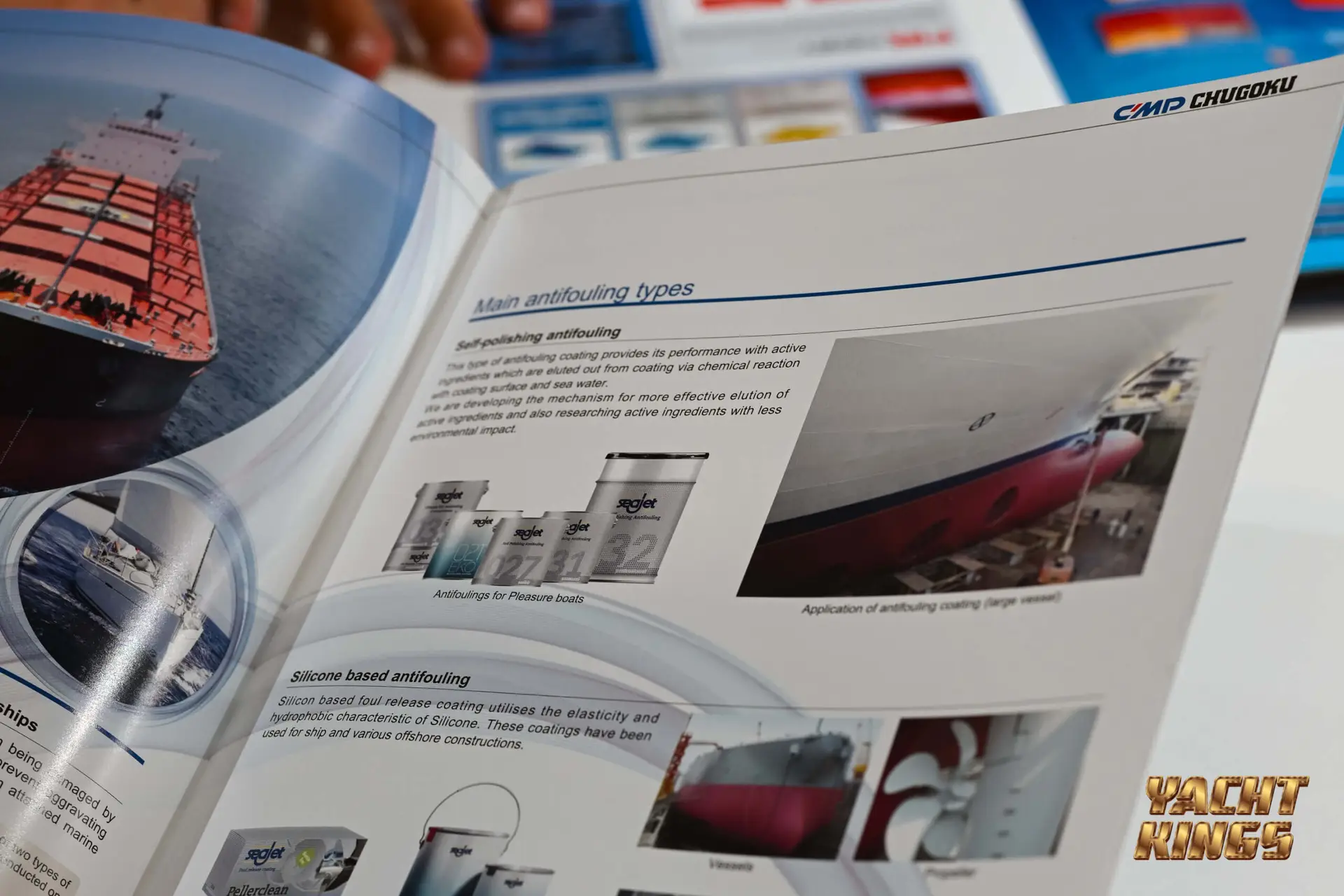

CMP’s marine coatings aren’t decorative—they’re engineered for endurance. Their SEA GRANDPRIX series, built on silyl polymer technology, self-polishes to minimize drag, improve speed, and enhance fuel economy. And for shipowners prioritizing sustainability? The BIOCLEAN RX series skips biocides entirely, opting for silicone-based foul-release coatings that comply with the world’s toughest environmental standards. This isn’t cosmetic—it’s chemistry working in defense of performance, efficiency, and long-term operational savings.

What Sustainability Actually Looks Like

While many companies greenwash their marketing, CMP backs its claims with action. Its Netherlands facility operates under a closed production system that eliminates solvent emissions, and the factory runs on solar power. Every product, every process, every innovation is developed with environmental performance as a non-negotiable. This isn’t the future of coatings—it’s happening now, and it’s setting a higher bar for the entire marine industry.

Digital Intelligence Meets Coating Science

CMP’s brilliance doesn’t end at the brush. Their CMP-MAP service integrates hull coating data with real-world vessel performance analytics. This platform predicts fuel consumption, tracks antifouling effectiveness, and even helps shipowners improve their Carbon Intensity Indicator (CII) ratings. In an industry facing relentless pressure to decarbonize, CMP has connected its physical product line with a digital ecosystem that helps owners make measurable, money-saving decisions.

A Global Force with Local Expertise

With 14 production sites and a footprint in over 105 countries, CMP doesn’t just ship paint—they offer localized support tailored to regional waters, regulations, and hull conditions. In Japan, they hold the lion’s share of the market for a reason: consistency, quality, and coatings that perform exactly as promised, season after season. From commercial tankers to superyachts, their products are trusted by owners who understand that protection starts before you leave the dock.

Built for More Than Ships

Their protective innovations aren’t limited to hulls. They’re used across bridges, offshore platforms, steel structures, and critical infrastructure—many meeting rigorous certifications like NORSOK M-501. This crossover expertise reinforces one core belief: a coating isn’t just a layer. It’s a system of protection, engineered to perform in extreme, high-risk environments.

What the Industry Needs to Hear

So why are so many vessels still running inferior coatings that cost more in the long run? CMP’s combination of science, sustainability, and smart tech is proof that innovation doesn’t need to scream to make an impact. It just needs to work—and it does. As shipowners face tighter emissions rules and rising fuel costs, the smarter choice is already here. It’s just been too quiet for too long.