- Technology and Innovation

No More Scratches: The Custom Foam That Just Solved Yachting’s Maintenance Problem

The Silent Shift: From Hardwood to Smart Foam

The visual aesthetic of yacht decking has traditionally been dictated by heavy, expensive, and high-maintenance materials. SeaDek—a company born from the technical precision of manufacturing fiberglass surfboard fins—is driving a quiet, profound revolution. Their product, made from closed-cell PE/EVA foam, is not a simple alternative; it is a superior solution that has rapidly been adopted by top boat builders worldwide. SeaDek’s presence at IBEX 2025 is a confident assertion that the days of unnecessary weight, maintenance, and complex installation are over.

The OEM Advantage: Saving Time and Weight

SeaDek’s primary appeal to manufacturers is its pure efficiency. By replacing molded-in non-skid or labor-intensive painted textures, SeaDek saves OEMs significant time and money during the manufacturing process. Its application is robust: an acrylic-based high bond pressure-sensitive adhesive ensures a lasting bond with a simple peel-and-stick application, requiring no hardware. This simplified process drastically speeds up the production line, all while guaranteeing exceptional traction and consistent quality.

Performance That Counts: Comfort and Protection

For the yacht owner, the benefits extend directly to comfort and asset protection. SeaDek offers exceptional traction, even when wet, drastically improving safety. Furthermore, its shock absorption characteristics decrease fatigue, a critical factor for long days on the water. The material also protects boat surfaces against scratches, chips, and dents, maintaining the vessel’s value. Finally, its noise reduction qualities are ideal for professional fishermen and owners who value serenity at anchor.

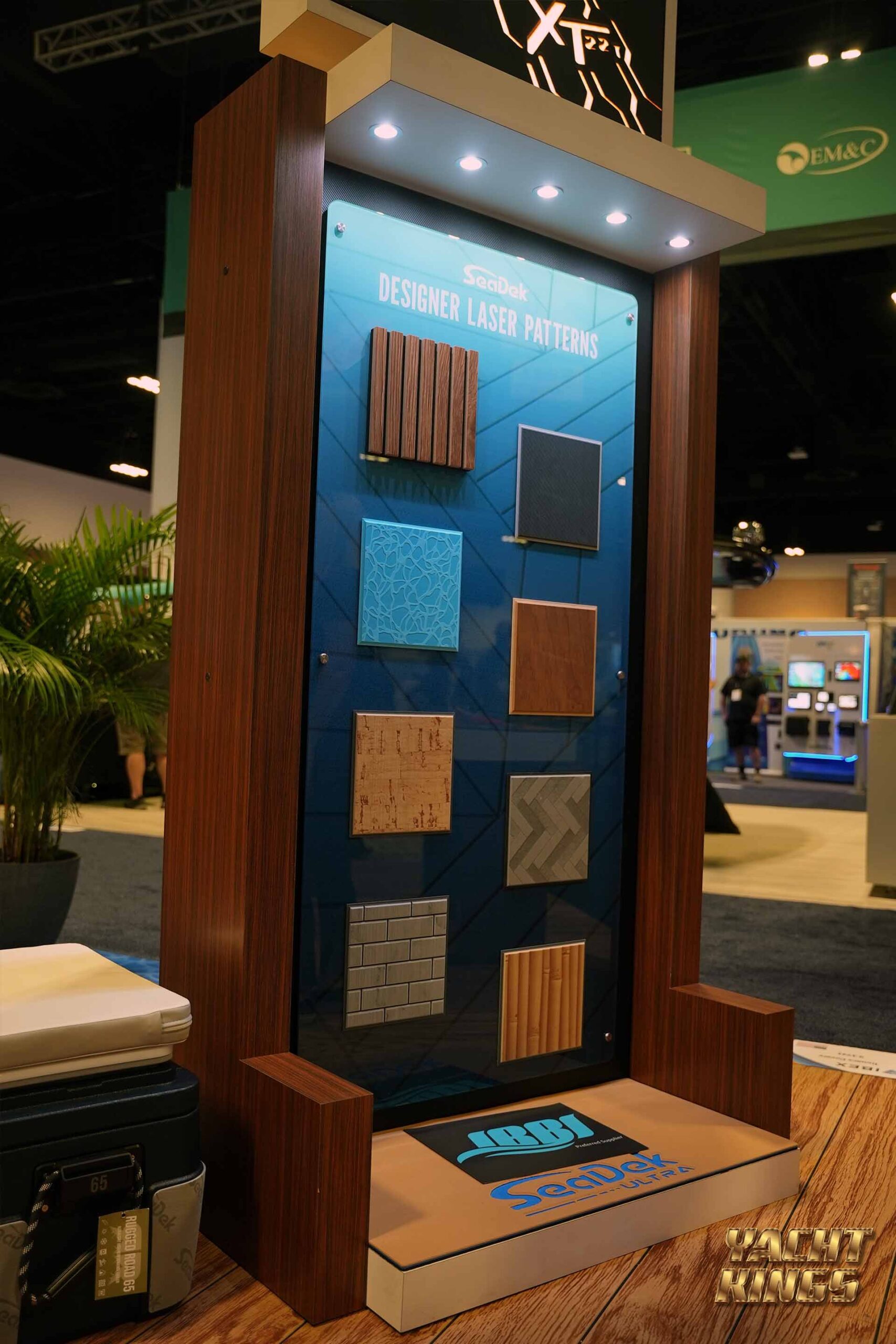

The Aesthetics of Freedom: Customization as Standard

SeaDek operates on the principle that personalization should be accessible. The material is available in a huge array of textures, thicknesses, and colors, providing virtually endless customization options. Premium options include triple lamination, custom routing, and laser patterning, allowing owners to achieve a look that mimics teak or create a completely unique design. This flexibility allows SeaDek to be tailored to fit every application on nearly any type of boat, from anti-fatigue helm station pads to custom coaming bolsters.

The Verdict: The Final Word on Decking

SeaDek’s journey from manufacturing surfboard fins to pioneering EVA technology for marine decking is a testament to genuine innovation. The brand cemented itself as a standard for quality and performance by constantly improving its products and manufacturing processes. For builders, the IBEX display proves that SeaDek is the strategic partner for efficient production; for owners, it is the ultimate choice for enhancing comfort, safety, and the long-term value of their vessel.