- Technology and Innovation

Engine Room to Bulkhead: The Full-Spectrum Engineering That Solved Yacht Integrity

The Engineering Mandate: Fire and Water Integrity

In high-stakes yacht construction, achieving absolute integrity in bulkheads requires custom solutions, not standard parts. Halyard, a long-established specialist in marine engineered solutions, showcased its expanded capabilities at METSTRADE 2025. As the distributor for Ucalsa Custom Metal Solutions in the UK and Ireland, Halyard now provides bespoke weathertight, watertight, and fire-rated doors and hatches. Ucalsa specializes in tailor-made solutions, ensuring every closure is optimized for the customer’s specific technical requirements, rather than relying on a limited standard range.

A60 Security: The Certified Standard

The critical appeal of the Ucalsa partnership is the level of compliance and customization offered. Doors are available with MED and UKCA certified fire ratings ranging from A0, A15, A30, up to the stringent A60 certification. Furthermore, watertight doors inserted below the freeboard deck are designed to withstand static water pressure and are individually verified by a watertightness test of the required water column. This meticulous level of verification, combined with the ability to customize shell and pantograph doors with manual or hydraulic closures, is essential for large superyachts operating under LYC and PYC standards.

Engine Room Resilience: Lloyd’s Approved Components

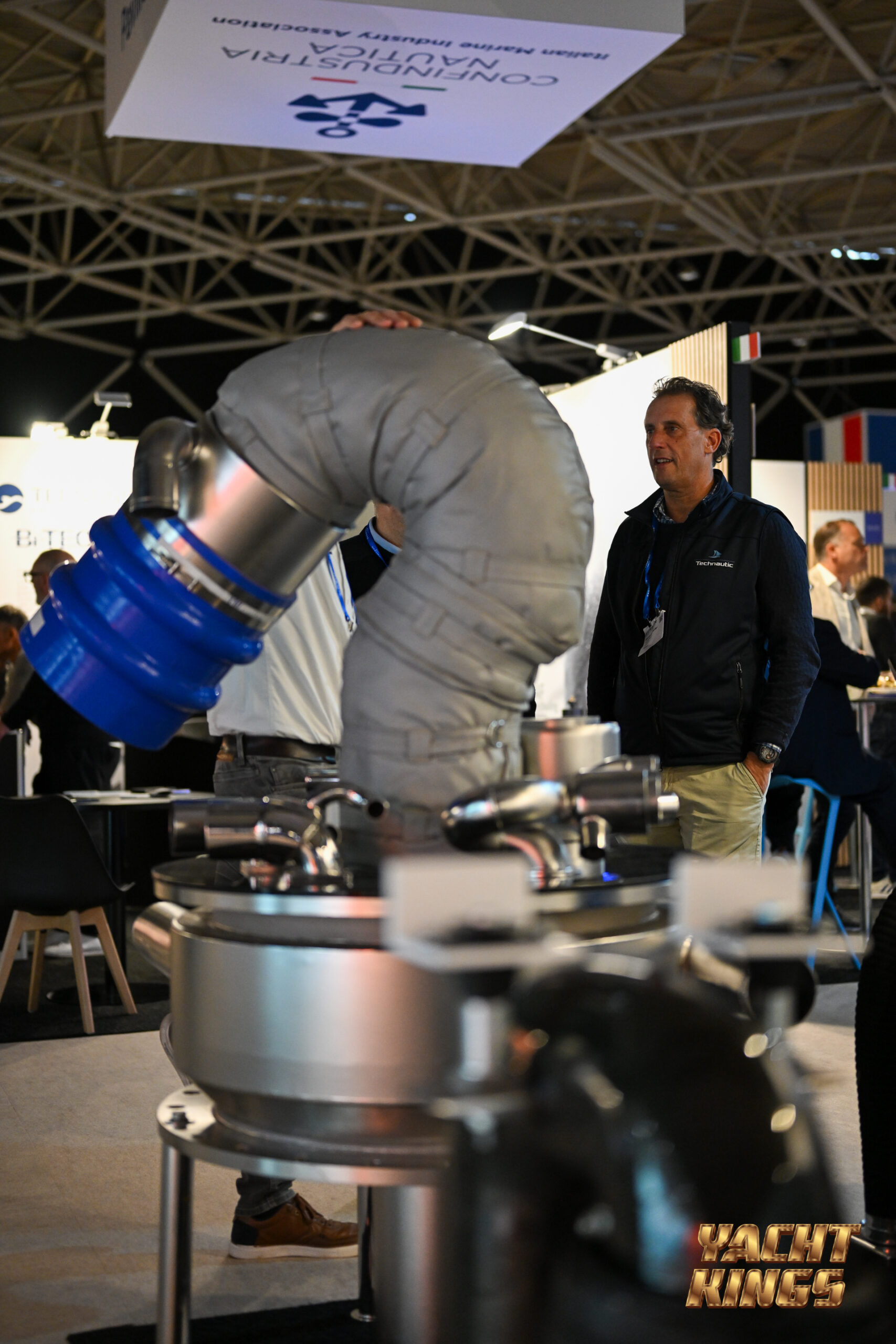

Halyard’s core expertise in marine exhaust systems remains a crucial offering. The company manufactures a range of rubber, silicone, or Nomex hoses, bellows, and connectors specifically for marine diesel exhaust systems. These components are manufactured to Lloyd’s Type Approval for use in exhaust applications. The integrity of these components is vital for reducing noise, ensuring cleaner operation, and improving life onboard for owners and crew alike. Halyard’s in-house design capability ensures that whether the system is water-cooled or dry, the components are optimized for peak performance.

The Integrated Approach: Consulting and Service

Halyard defines itself as a consultative partner, offering expertise that spans the vessel’s critical systems. Since 1979, the company has offered a one-stop shop with in-house design and manufacturing for their own exhaust systems, complemented by distribution of technical products like Ucalsa hatches, Aquadrive anti-vibration systems, and Steelhead cranes. Their service extends to installation support, commissioning, fault finding, and maintenance for a wide variety of systems, ensuring clients receive dependable global service.

The Verdict: The Final Word on Bespoke Engineering

The Halyard exhibit at METSTRADE 2025 confirmed the importance of their full-system engineering strategy. By providing custom-made, high-certification metal solutions (Ucalsa) alongside precision-engineered exhaust components (hoses and bellows), Halyard addresses critical safety and operational demands. For yacht builders and yards across the leisure market, this partnership delivers technical excellence and compliance, supporting cleaner, quieter, and more efficient vessel operation.